About the Project

Motivation: The increasing demand for knee replacement surgeries due to degenerative diseases has necessitated the design of lighter, more durable prosthetic knee joints. This project aims to develop and analyze a prosthetic knee joint capable of sustaining high loads while maintaining biomechanical compatibility and cost-efficiency.

Objective: The project seeks to design and analyze a flexible prosthetic knee joint using materials with high longevity, low maintenance, and excellent biomechanical compatibility. It focuses on von-Mises stress, total deformation, and strain distribution under varying loads.

Technical Overview

Design and Analysis

The project utilized the following tools and methodologies:

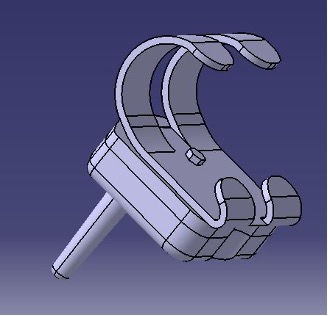

- CAD Modeling: CATIA V5 was used for creating the 3D model of the knee prosthesis.

- Finite Element Analysis (FEA): ANSYS 14.5 was employed to simulate stress, deformation, and strain distributions under static conditions.

- Material Selection: Analysis of biomaterials such as TI-6AL-4V, TI-6AL-7NB, and ABS for their suitability in prosthetic applications.

- Boundary Conditions: Load simulations considered static and dynamic forces during walking and running activities.

Material Properties

The study evaluated various biomaterials:

- TI-6AL-4V: High strength, corrosion resistance, and biocompatibility.

- TI-6AL-7NB: Similar properties to TI-6AL-4V with enhanced mechanical performance.

- ABS: Lightweight and cost-effective for temporary implants.

- Stainless Steel 316L: Limited corrosion resistance but widely used for temporary orthopedic implants.

Results

- Stress Distribution: TI-6AL-7NB showed optimal stress distribution and resistance under high loads.

- Deformation: Total deformation was minimized using titanium alloys compared to ABS and stainless steel.

- Durability: Titanium alloys exhibited superior long-term durability and biocompatibility.

Challenges and Solutions

- Complex Geometry: Accurate modeling of the knee joint's anatomical structure using CATIA.

- Material Selection: Extensive testing of biomaterials to ensure biocompatibility and mechanical reliability.

- Load Analysis: Iterative simulations in ANSYS to refine load distribution and optimize geometry.

Technologies Used

- CAD Software: CATIA V5 for 3D modeling.

- FEA Software: ANSYS 14.5 for structural analysis.

- Materials: TI-6AL-4V, TI-6AL-7NB, Stainless Steel 316L, ABS.

Future Scope

- Advanced Materials: Exploration of next-generation biomaterials with improved fatigue resistance.

- Dynamic Analysis: Incorporating real-time gait data to refine stress and deformation simulations.

- AI Integration: Using machine learning to predict wear patterns and optimize designs further.