About the Bioinspired Pier Project

Motivation: This project was driven by the need to create a strong, durable, and lightweight structure for underwater and high-stress environments. Taking inspiration from nature, the shiitake mushroom and loofah sponge served as models for adhesion and structural integrity, respectively.

Inspiration: The shiitake mushroom's blunt edges and robust cap-stem structure inspired the adhesion method, while the porous lattice of the loofah sponge informed the energy absorption and stress distribution design. Together, these biomimetic elements provided a durable and resilient structure suitable for demanding applications.

Technical Overview

Adhesion Design

- Mushroom-like extrusion design optimized for underwater adhesion.

- Dimensions: 100x100 mm surface area, 3 mm base, 4.45 mm top, 6.1 mm spacing for effective attachment and detachment.

- Tested to withstand 20 kg force in benchtop trials.

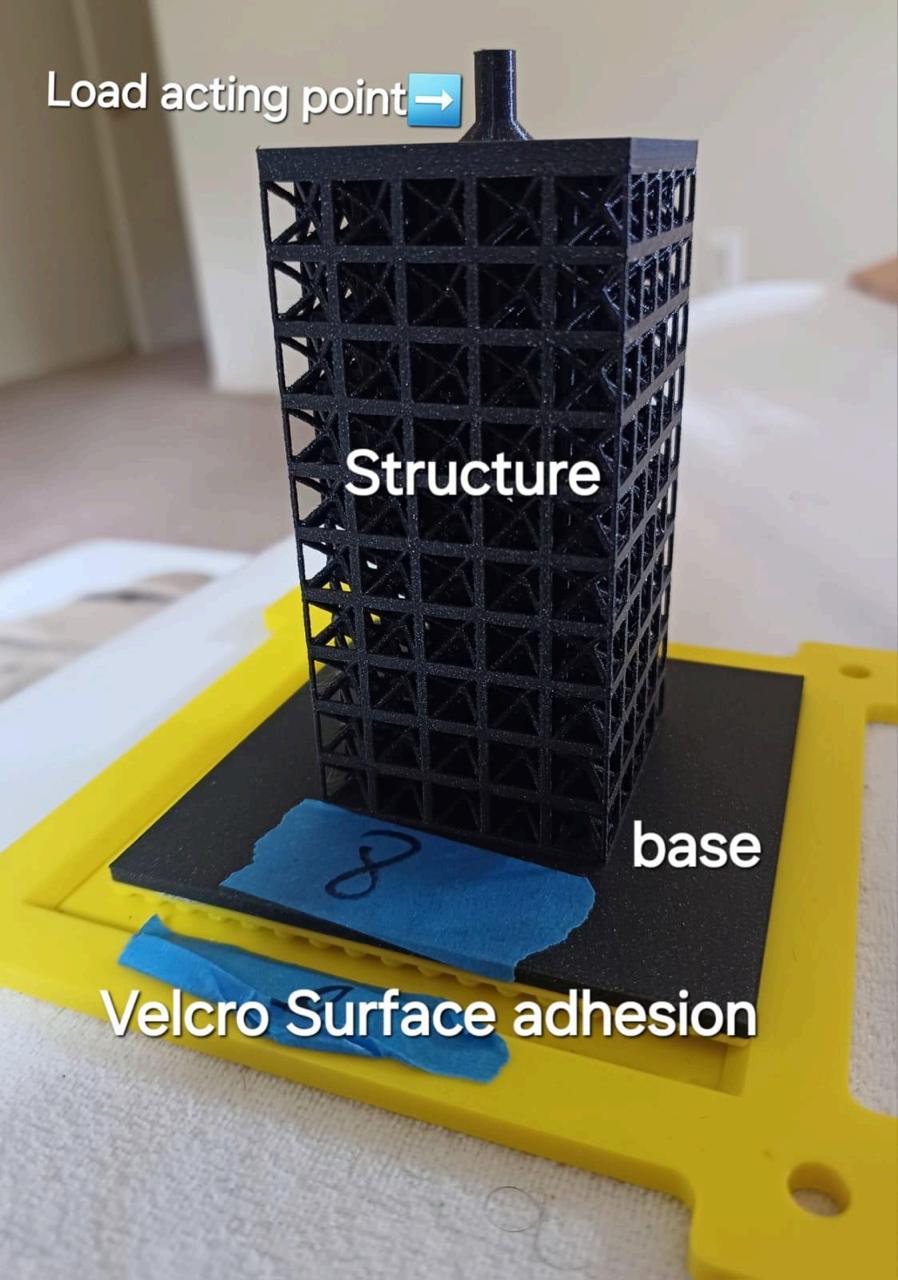

Lattice Structure

- Loofah sponge-inspired lattice structure for load distribution and resilience.

- Dimensions: 50x50x100 mm with a weight of 50.33 g.

- Load-bearing capacity: 7,000 N peak under vertical load, with deformation starting at 4,000 N.

- Failure mode: Localized buckling under extreme loads.

Performance Testing

- Hydraulic Press Test: Elastic deformation observed up to 2 mm at 7,000 N, with stabilized deformation around 12 mm at 4,000 N.

- Load Test: Velcro attachment maintained integrity up to 10 pounds; separation occurred beyond this point without structural damage.

Challenges and Solutions

- Adhesion: Optimized Velcro spacing for improved attachment and detachment.

- Load Distribution: Increased lattice thickness to enhance structural integrity under high stress.

Technologies Used

- Design: CAD modeling using Onshape for precise structural representation.

- Testing: Hydraulic press for force-displacement analysis and load testing setup.

- Materials: Water-resistant polymers for adhesion and structural components.

Results

- Successfully demonstrated a lightweight, durable design suitable for underwater conditions.

- Adhesion design effectively withstood human-level force applications.

- Structural integrity maintained under hydraulic and load testing conditions.

Future Scope

- Enhance connection strength by modifying Velcro spacing and material composition.

- Develop larger-scale models for industrial and marine applications.

- Incorporate IoT-enabled sensors for real-time monitoring and performance analysis.

Videos

Watch the first video on Hydraulic Test: Play Video

Watch the second video on Strength Test: Play Video